Introduction

Fire safety has become a critical priority in modern construction, especially as building designs grow more complex and regulations more demanding. One of the most effective materials used for passive fire protection today is Fire Resistant Gypsum Plaster, a specialized plaster designed to slow down fire spread and maintain structural stability during high-temperature exposure.

Unlike conventional interior plasters, fire-resistant gypsum-based systems are engineered to perform under extreme conditions. The natural properties of gypsum allow it to release chemically bound water when exposed to heat, helping reduce temperature rise and delay structural failure. This makes Fire Resistant Gypsum Plaster a reliable solution for protecting walls, ceilings, and partitions in residential, commercial, and industrial buildings.

In recent years, architects and engineers have increasingly turned to Fireproof Gypsum Plaster solutions as part of broader fire-rated building systems. When properly specified and applied, these gypsum-based materials contribute significantly to meeting fire safety standards while maintaining design flexibility and cost efficiency.

This article explores six powerful reasons why fire resistant gypsum is widely used in construction projects, how it compares to alternative fire protection materials, and why high-quality industrial gypsum products play a crucial role in improving overall building safety.

What Is Fire Resistant Gypsum Plaster?

Fire Resistant Gypsum Plaster is a specialized type of gypsum plaster formulated to improve a building’s performance under fire conditions. Unlike standard interior plasters that focus primarily on aesthetics and surface smoothness, fire-resistant gypsum systems are engineered with safety as a core function.

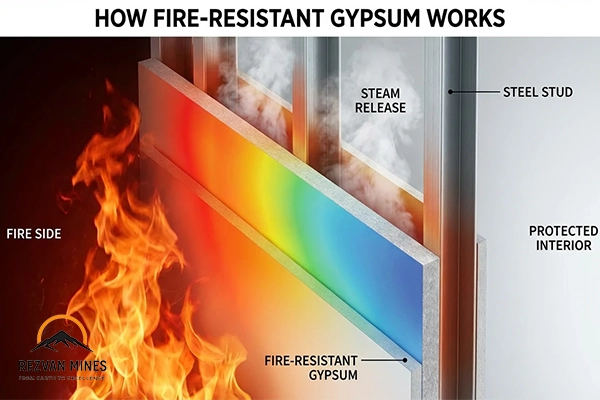

The fire-resistant capability of gypsum comes from its natural chemical structure. Gypsum contains crystallized water molecules that are released as steam when exposed to high temperatures. This process absorbs heat and reduces the rate at which fire spreads across walls and ceilings, making it an essential component of modern fire rated gypsum systems.

In construction projects where fire safety regulations are strictly enforced, fire resistant gypsum is often specified as part of a broader passive fire protection strategy. It is commonly applied in fire-rated partitions, shaft walls, stairwells, and interior surfaces where delaying fire progression is critical for occupant safety.

Although often referred to as Fireproof Gypsum Plaster, this material is technically fire resistant rather than completely fireproof. However, when correctly installed and combined with certified construction systems, it significantly enhances the fire performance of building elements while remaining lightweight and compatible with standard application methods.

How Fire Resistant Gypsum Works Under High Temperatures

To understand why Fire Resistant Gypsum Plaster is widely used in modern construction, it is essential to examine how it behaves when exposed to fire. Unlike many conventional construction materials that rapidly lose strength under high temperatures, gypsum-based systems respond through a controlled physical and chemical process.

Thermal Behavior of Fire Resistant Gypsum

Gypsum is primarily composed of calcium sulfate dihydrate, a material that contains chemically bound water within its crystalline structure. When temperatures rise during a fire, this water does not immediately evaporate. Instead, it is gradually released as steam at approximately 100–120°C, a process that absorbs a significant amount of heat.

This heat absorption slows down the temperature increase on the unexposed side of walls and ceilings, effectively acting as a thermal barrier. As a result, fire resistant gypsum helps delay fire penetration and reduces the rate at which flames spread through interior surfaces.

Role in Passive Fire Protection Systems

In passive fire protection strategies, materials are designed to work without mechanical intervention. Fire Resistant Gypsum Plaster plays a critical role in these systems by maintaining its integrity for a defined fire rating period. During a fire event, the plaster continues to protect underlying structural elements, buying valuable time for evacuation and emergency response.

For this reason, gypsum-based solutions are a key component of fire rated gypsum systems used in partitions, shafts, and ceiling assemblies. When combined with proper framing and insulation, they contribute to meeting international fire resistance standards.

Fire Resistance vs Fireproof Performance

The term Fireproof Gypsum Plaster is commonly used in construction markets, but from an engineering perspective, it is more accurate to describe gypsum as fire resistant rather than fireproof. No plaster can completely withstand unlimited fire exposure. However, the controlled dehydration process of gypsum allows it to perform predictably and reliably under fire conditions.

Compared to many traditional plasters, Fire Resistant Gypsum Plaster maintains its form longer, suffers less cracking during early fire stages, and provides superior performance as part of layered wall and ceiling systems.

Reason 1: Enhanced Fire Safety and Passive Fire Protection

One of the primary reasons Fire Resistant Gypsum Plaster is widely used in construction projects is its contribution to overall fire safety. In buildings, fire-related damage is rarely caused by flames alone; rapid heat transfer and early structural failure are often the main factors that turn small fires into large-scale disasters.

Fire resistant building materials are specifically designed to slow this process. Gypsum-based plasters perform exceptionally well in passive fire protection systems by reducing heat transmission through walls and ceilings. This delay can be critical, as it provides occupants with additional evacuation time and allows emergency services to respond more effectively.

Unlike active fire protection systems such as sprinklers or alarms, passive fire protection relies entirely on material performance. Fire Resistant Gypsum Plaster requires no mechanical activation and maintains its function continuously throughout the building’s lifespan. This makes it a reliable choice for high-occupancy structures, industrial facilities, and complex architectural layouts.

Contribution to Passive Fire Protection Strategies

In modern construction, passive fire protection is a mandatory design consideration rather than an optional upgrade. Gypsum-based plasters are frequently integrated into passive fire protection materials due to their predictable behavior under high temperatures. When exposed to fire, the gradual release of bound water slows temperature rise and reduces the risk of flashover in adjacent spaces.

As part of layered wall assemblies, fire resistant gypsum helps protect load-bearing components and prevents early collapse. Compared to conventional surface finishes, it offers significantly better performance in delaying fire spread, making it suitable for applications where safety and compliance are equally important.

Reason 2: Compliance with Fire Safety Building Codes

Compliance with fire safety regulations is one of the most decisive factors in material selection for modern construction projects. Fire Resistant Gypsum Plaster is widely specified because it helps buildings meet mandatory fire resistance requirements without adding structural complexity or excessive cost.

Most national and international building codes emphasize the importance of limiting fire spread, maintaining compartmentation, and preserving load-bearing capacity for a defined period. Gypsum-based fire-resistant systems are well aligned with these objectives, making them a common solution in regulated construction environments.

Meeting Fire Rating Requirements

Walls, ceilings, and partitions are often required to achieve specific fire ratings, such as 30, 60, or 120 minutes. Fire Resistant Gypsum Plaster, when applied as part of certified assemblies, contributes directly to achieving these ratings. Its predictable thermal performance allows designers and engineers to calculate fire resistance more accurately compared to many alternative finishing materials.

Unlike decorative plasters that offer little or no fire protection, fire resistant plaster for walls plays a functional role in delaying heat transfer and maintaining surface integrity. This makes it particularly suitable for high-risk zones such as stairwells, escape routes, service shafts, and industrial interiors.

Regulatory Acceptance in Modern Construction

Building authorities and fire safety consultants tend to favor materials with established performance histories. Gypsum has been used for decades in fire-rated construction, and its properties are well documented in fire testing standards. As a result, Fire Resistant Gypsum Plaster is regularly accepted within approved fire rated gypsum systems across residential, commercial, and industrial projects.

From a compliance perspective, gypsum-based solutions also reduce the risk of inspection failures. Their consistent behavior under fire exposure helps ensure that constructed elements perform as expected during certification tests and on-site evaluations.

In projects where safety, legality, and long-term performance are non-negotiable, Fire Resistant Gypsum Plaster offers a reliable path to meeting fire safety building codes while preserving design flexibility.

Reason 3: Improved Structural Stability During Fire Exposure

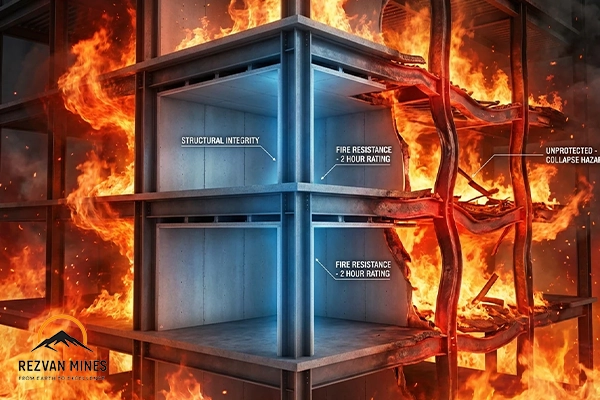

Fire resistance is not only about stopping flames; it is primarily about maintaining structural integrity when temperatures rise rapidly. One of the key advantages of Fire Resistant Gypsum Plaster is its ability to support structural fire resistance by slowing down thermal degradation of building components.

During a fire, many conventional surface materials crack, detach, or lose cohesion within minutes. This early failure exposes underlying elements such as masonry, steel, or concrete to direct heat, accelerating structural damage. In contrast, Fire Resistant Gypsum Plaster remains stable for a longer period, acting as an insulating barrier that reduces thermal shock and delays material fatigue.

Load-Bearing Protection in Fire Conditions

Although gypsum plaster itself is not load-bearing, its role in protecting load-bearing elements is critical. When applied correctly, fire resistant plaster for walls shields substrates from extreme temperature spikes. This is especially important in steel-framed structures, where uncontrolled heat exposure can quickly reduce load-bearing capacity.

Gypsum’s low thermal conductivity helps maintain internal temperatures below critical thresholds, supporting structural fire resistance in both vertical and horizontal assemblies. As part of tested fire rated gypsum systems, this material contributes to preserving structural stability long enough to prevent progressive collapse.

Reduced Risk of Structural Failure

Fire-induced collapse is often caused by uneven heating or premature material failure. One of the overlooked benefits of Fire Resistant Gypsum Plaster is its uniform thermal performance. By distributing heat more evenly across surfaces, it helps prevent localized overheating, which is a common trigger for cracking and detachment in conventional finishes.

In high-rise buildings, industrial facilities, and infrastructure projects, even a small delay in structural failure can significantly reduce physical damage and financial loss. For this reason, Fire Resistant Gypsum Plaster is increasingly specified in applications where fire resistant construction materials must deliver both safety and durability under extreme conditions.

Reason 4: Cost Efficiency and Long-Term Economic Benefits

Fire protection solutions are often assumed to be expensive, complex, and difficult to justify from a budget perspective. This assumption is partly true for specialized coatings and advanced fireproof systems—but Fire Resistant Gypsum Plaster is a notable exception. It delivers reliable fire protection while remaining economically efficient across the entire lifecycle of a building.

From procurement to installation, gypsum-based solutions generally cost less than many alternative fire resistant construction materials. This makes them especially attractive for large-scale residential, commercial, and industrial projects where cost control is critical and margins are under constant pressure.

Lower Installation and Labor Costs

One of the key economic strengths of Fire Resistant Gypsum Plaster lies in its ease of application. Unlike intumescent coatings or multi-layer fireproof panels, gypsum plaster can often be applied using standard tools and familiar construction techniques. This reduces labor training requirements and minimizes installation time.

For contractors, faster application directly translates into reduced labor expenses and tighter project schedules. In high-volume builds, these efficiencies compound, making fire resistant plaster for walls a practical choice not only from a safety standpoint but also from a financial one.

Reduced Maintenance and Repair Expenses

Cost efficiency is not limited to the construction phase. Over time, Fire Resistant Gypsum Plaster tends to require less maintenance compared to exposed fireproof coatings that may degrade, crack, or lose effectiveness if damaged. Gypsum systems are typically more stable, especially in interior environments where mechanical impact rather than weather exposure is the main concern.

When maintenance is required, repairs are usually straightforward and localized. This reduces long-term operational costs and helps maintain compliance with fire safety standards without large-scale material replacement.

Favorable Cost-to-Performance Ratio

In value-engineered projects, performance per unit cost is a critical metric. Fire Resistant Gypsum Plaster offers a strong balance between fire resistance duration, installation simplicity, and affordability. Compared to premium fireproof systems, it often delivers sufficient fire protection without unnecessary overengineering.

For developers and facility owners, this balanced cost-to-performance ratio makes Fire Resistant Gypsum Plaster a financially sound investment—especially in projects where regulatory compliance and basic fire resistance are mandatory but extreme fire exposure scenarios are unlikely.

Reason 5: Versatility in Modern Construction and Architectural Design

Modern construction projects demand materials that combine performance with flexibility. Fire Resistant Gypsum Plaster meets this demand by offering fire protection without restricting architectural design. Unlike rigid fireproof boards or heavy fire-rated panels, gypsum plaster adapts easily to a wide range of structural and aesthetic requirements.

This versatility is one of the main reasons fire resistant building materials based on gypsum are widely preferred in both functional and design-driven projects.

Adaptability Across Different Building Types

Fire Resistant Gypsum Plaster is suitable for residential buildings, commercial interiors, industrial facilities, and public infrastructure. It can be applied to concrete, masonry, steel-framed, and composite substrates, making it a practical solution for mixed-use developments where construction systems vary within the same project.

In complex layouts involving curved surfaces, detailed ceilings, or integrated service routes, fire resistant plaster for walls provides a level of adaptability that rigid fireproof components simply cannot match. This allows designers to maintain visual continuity while still meeting safety requirements.

Compatibility with Modern Interior Systems

Today’s interiors often incorporate lighting systems, acoustic treatments, HVAC components, and concealed cabling. Fire Resistant Gypsum Plaster integrates seamlessly with these systems, especially when used as part of coordinated fire rated gypsum systems.

Its smooth finish supports additional layers such as paint, fire-rated coatings, and decorative surfaces without compromising fire performance. This compatibility reduces the need for secondary materials, simplifying both design coordination and on-site execution.

Design Freedom Without Sacrificing Fire Protection

A common compromise in fire-safe design is sacrificing aesthetics for compliance. Fire Resistant Gypsum Plaster challenges this trade-off. It enables architects to achieve clean lines, complex geometries, and contemporary finishes while retaining reliable fire resistant construction materials at the core of the building envelope.

For developers and designers alike, this balance between safety and flexibility makes Fire Resistant Gypsum Plaster a strategic choice in modern construction and interior architecture.

Reason 6: Sustainability and Environmental Performance

Sustainability is no longer a marketing buzzword in construction; it is a regulatory, economic, and reputational requirement. Fire Resistant Gypsum Plaster aligns well with modern sustainability goals by offering fire protection with a lower environmental footprint compared to many synthetic fireproof systems.

Gypsum is a naturally abundant mineral, and in many regions it is sourced and processed with relatively low environmental impact. This makes Fire Resistant Gypsum Plaster a practical option for projects that aim to balance safety, performance, and environmental responsibility.

Reduced Environmental Impact Over the Building Lifecycle

Unlike complex fireproof coatings that rely on petrochemical components, fire resistant construction materials based on gypsum are often simpler in composition and easier to manage throughout the building lifecycle. From production and application to maintenance and eventual demolition, gypsum systems tend to generate less hazardous waste.

In fire scenarios, Fire Resistant Gypsum Plaster does not release toxic fumes or dense smoke, which contributes not only to occupant safety but also to overall environmental performance. This characteristic further strengthens its position among fire resistant building materials specified for healthcare, educational, and public buildings.

Compatibility with Green Building Standards

Many sustainable construction frameworks prioritize material transparency, durability, and safety. Fire Resistant Gypsum Plaster is frequently compatible with green building objectives because of its durability, service life, and potential contribution to responsible material use.

When integrated into certified fire rated gypsum systems, gypsum-based fire protection supports long-term performance without frequent replacement. This reduces material consumption over time and aligns with sustainability-driven design strategies focused on resource efficiency.

A Balanced Solution for Safety and Sustainability

While no construction material is entirely impact-free, Fire Resistant Gypsum Plaster offers a rare balance: reliable fire protection combined with acceptable environmental performance. For developers and specifiers seeking to meet fire safety requirements without undermining sustainability targets, it represents a rational and defensible choice.

Conclusion: Why Fire Resistant Gypsum Plaster Matters in Modern Construction

Fire safety in construction is not achieved through a single feature or material; it is the result of deliberate, standards-driven choices. As this article has demonstrated, Fire Resistant Gypsum Plaster plays a critical role in creating safer, more resilient, and more compliant buildings without imposing unnecessary cost or design limitations.

From enhancing passive fire protection to supporting structural stability under extreme heat, gypsum-based fire-resistant systems offer predictable and proven performance. Their compatibility with building codes, adaptability across project types, and economic efficiency make them a practical solution rather than a theoretical upgrade.

Unlike products marketed as “fireproof,” which often oversimplify a complex engineering reality, Fire Resistant Gypsum Plaster delivers measurable fire resistance that aligns with real-world fire scenarios. Its use within certified fire rated gypsum systems allows designers, contractors, and property owners to meet safety obligations while maintaining control over budgets and construction timelines.

In modern construction—where regulatory scrutiny, sustainability expectations, and performance requirements continue to rise—choosing materials that balance all three is no longer optional. Fire Resistant Gypsum Plaster represents that balance: reliable fire safety, regulatory acceptance, long-term value, and architectural flexibility.

Why Choose Fire Resistant Gypsum from Rezvan Mines?

At Rezvan Mines, fire resistance is treated as an engineering responsibility, not a marketing claim. Our gypsum-based products are developed to meet the real demands of modern construction projects, where safety, consistency, and compliance matter more than labels.

By integrating Fire Resistant Gypsum Plaster from Rezvan Mines into your projects, you benefit from:

- Proven performance within fire-resistant building assemblies

- Compatibility with regulated fire resistant construction materials standards

- Consistent quality suitable for large-scale and industrial applications

- A material solution designed for both safety and long-term efficiency

Whether you are designing residential developments, commercial interiors, or industrial facilities, Rezvan Mines provides gypsum solutions that support fire safety strategies without compromising practicality or cost control.