with building regulations, long-term costs, and risk exposure.

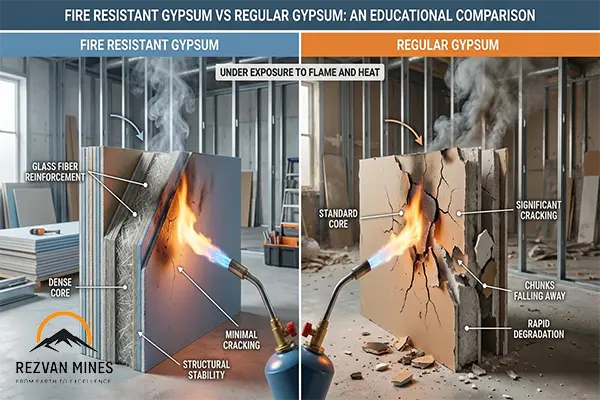

While regular gypsum plaster is widely used for interior finishes, it does not offer the same level of performance under fire conditions as fire resistant gypsum. Understanding the differences between these two materials is essential for contractors, developers, and project managers who need to balance safety, cost, and application requirements.

In this guide, we compare fire resistant gypsum vs regular gypsum by focusing on performance, fire behavior, applications, and cost implications, helping you determine which option is appropriate for your specific construction project.

What Is Fire Resistant Gypsum?

Fire resistant gypsum is a gypsum-based construction material formulated to withstand fire exposure for a defined period of time without losing its structural integrity. Unlike standard gypsum, it is engineered to slow heat transmission and support passive fire protection systems in buildings.

This type of gypsum typically contains:

- Reinforcing fibers

- Modified gypsum core composition

- Additives that improve thermal stability under high temperatures

When exposed to fire, fire resistant gypsum delays heat penetration and helps maintain surface stability, providing valuable extra time for evacuation and emergency response. For this reason, it is commonly used in areas where fire performance is regulated or critical.

Typical applications include:

- Fire-rated walls and ceilings

- Stairwells and escape corridors

- Technical and service rooms

- Commercial and industrial buildings

Fire resistant gypsum is designed to meet specific fire resistance ratings (such as 30, 60, or 120 minutes), making it suitable for projects that must comply with local or international fire safety standards.

What Is Regular Gypsum Plaster?

Regular gypsum plaster is a widely used interior finishing material valued for its smooth surface, ease of application, and cost efficiency. It is designed primarily for aesthetic purposes rather than fire protection, making it suitable for environments where fire resistance is not a critical requirement.

This type of gypsum is composed mainly of calcium sulfate hemihydrate, which allows it to set quickly and provide an even finish on walls and ceilings. However, unlike fire resistant gypsum, it lacks reinforcing fibers or specialized additives that enhance performance under high temperatures.

When exposed to fire, regular gypsum plaster offers limited resistance. Although gypsum naturally contains chemically bound water that provides short-term heat absorption, this effect is temporary. Once the moisture is released, the material rapidly loses strength and may crack or degrade under continued heat exposure.

Key characteristics of regular gypsum plaster include:

- Fast setting and easy workability

- Smooth and uniform surface finish

- Lower material and installation costs

- Limited fire performance compared to fire-rated alternatives

Because of these properties, regular gypsum is commonly used in:

- Residential interiors

- Offices and low-risk commercial spaces

- Decorative ceilings and wall finishes

- Areas without strict fire-rating requirements

From a regulatory perspective, regular gypsum plaster is generally not intended for use in fire-rated assemblies. It may still be allowed in certain building zones, but only where fire safety standards do not mandate tested fire resistance ratings.

In practical terms, regular gypsum plaster is an economical and efficient solution for projects focused on appearance and speed of execution. However, in locations where fire containment, evacuation safety, or code compliance is involved, substituting it for fire resistant gypsum can lead to non-compliance, increased liability, and higher long-term risk.

Key Differences Between Fire Resistant Gypsum and Regular Gypsum

Understanding the difference between fire resistant gypsum and regular gypsum is critical when selecting materials for buildings that must meet safety regulations. While both materials are gypsum-based, their behavior under heat exposure is fundamentally different.

Below are the most important technical and practical differences that directly affect safety, compliance, and performance.

Fire Resistance Rating of Gypsum

One of the most significant differences lies in the fire resistance rating of gypsum systems.

Fire resistant gypsum plaster is specifically tested to achieve defined gypsum fire rating levels, such as 30, 60, or 120 minutes, depending on system design and installation method. These ratings indicate how long the material can resist fire exposure while maintaining integrity.

In contrast, regular gypsum does not provide a certified fire rating on its own. While it may slow heat transfer briefly, it is not suitable for fire-rated assemblies.

Heat Resistance: Material Behavior Under Fire

Heat resistance gypsum plaster is engineered to remain stable under extreme temperatures. The internal structure includes additives and fibers that prevent early cracking and collapse.

Regular gypsum, however, loses strength quickly once internal moisture evaporates. As a result, its gypsum plaster fire performance deteriorates rapidly during sustained fire conditions.

This difference is a key reason why fire resistant materials are required in critical zones.

Fire Protection Gypsum Plaster vs Standard Gypsum

Fire protection gypsum plaster is designed as part of passive fire protection systems. Its role is to slow the spread of fire and maintain compartmentalization inside a building.

Regular gypsum plaster does not serve this purpose. It is intended for finishing and visual consistency, not for fire containment or protection.

This distinction becomes especially important in stairwells, corridors, and technical areas.

Fire Resistant Gypsum Plaster vs Regular Gypsum in Applications

The choice between fire resistant gypsum plaster vs regular gypsum depends largely on application type and local regulations.

Common fire resistant gypsum applications include:

- Fire-rated walls and ceilings

- Emergency escape routes

- Commercial and industrial facilities

Regular gypsum is typically used in:

- Residential interiors

- Decorative ceilings

- Low-risk office environments

Misusing regular gypsum in areas that require fire-rated materials can result in regulatory non-compliance.

Gypsum Plaster Fire Performance in Real Projects

From a practical construction standpoint, gypsum plaster fire performance influences insurance approval, inspection outcomes, and long-term risk management.

Projects that specify fire resistant gypsum benefit from predictable fire behavior and tested system performance. Regular gypsum offers no such guarantees when exposed to real fire scenarios.

Fire Resistant Gypsum Applications and Decision Criteria

Selecting the right material requires understanding when to use fire resistant gypsum.

Fire resistant gypsum is the correct choice when:

- Fire safety codes mandate rated assemblies

- Buildings have high occupancy or evacuation demands

- Fire containment is a design priority

Regular gypsum remains appropriate only when fire performance is not a regulated requirement.

Summary of Differences

In short, fire resistant gypsum vs regular gypsum is not a cosmetic comparison—it is a performance-driven decision that affects safety, compliance, and cost exposure.

The difference between fire resistant gypsum and regular gypsum becomes most visible under fire conditions, where only fire-rated materials can deliver reliable protection.

Application Comparison — Where Each Type Should Be Used

Choosing between fire resistant gypsum and regular gypsum is not just about material properties; it depends heavily on where and how the gypsum plaster is used. Misjudging this can lead to code violations, redesign costs, and safety risks.

Residential Buildings

In most residential units, regular gypsum plaster is widely used due to its lower cost and acceptable performance in low-risk areas. Bedrooms, living rooms, and decorative ceilings usually do not require certified fire resistance.

However, fire resistant gypsum applications become essential in:

- Emergency exits

- Shared corridors

- Electrical rooms

- Parking levels

In multi-story residential buildings, understanding when to use fire resistant gypsum is critical to meet modern fire safety standards.

Commercial and Office Spaces

Commercial buildings are far more sensitive in terms of gypsum plaster fire performance. Open offices, data rooms, and mechanical zones often require fire protection gypsum plaster to control flame spread and heat transfer.

Here, the fire resistance rating of gypsum systems directly affects:

- Insurance approval

- Occupancy permits

- Long-term maintenance costs

Using regular gypsum in these areas is often prohibited by regulations.

Industrial and High-Risk Facilities

Factories, warehouses, and production facilities generate higher heat loads and fire risks. In such environments, regular gypsum simply does not meet safety expectations.

Fire resistant gypsum plaster vs regular gypsum comparison becomes obvious here:

- Only fire-rated gypsum provides predictable fire behavior

- Certified gypsum fire rating is mandatory in most cases

Public Buildings and High-Occupancy Areas

Hospitals, schools, hotels, and airports require materials that support safe evacuation. Fire resistant gypsum plays a vital role in passive fire protection strategies.

In these buildings:

- Fire resistant gypsum applications are mandatory, not optional

- Regular gypsum is limited to non-critical zones only

Export and International Projects

For export-oriented construction projects, compliance with international standards is non-negotiable. Materials without tested gypsum fire rating often fail inspections.

This is where understanding the difference between fire resistant gypsum and regular gypsum impacts business success, not just construction quality.

When to Use Fire Resistant Gypsum (Practical Decision Guide)

Knowing when to use fire resistant gypsum is not a theoretical question. It is a practical decision that affects safety compliance, project approvals, and long-term liability. This section is designed to help engineers, contractors, and buyers make the correct choice based on real conditions.

Fire Safety Regulations and Code Requirements

In many countries, building codes strictly define where fire protection gypsum plaster must be used. Areas such as fire exits, escape corridors, technical shafts, and mechanical rooms require materials with a verified fire resistance rating of gypsum systems.

Using regular gypsum in these zones can result in:

- Failure during fire inspections

- Delays in occupancy permits

- Mandatory replacement at the contractor’s expense

This alone is often enough reason to justify fire resistant gypsum applications.

Occupancy Load and Human Safety

The higher the number of occupants, the greater the responsibility for fire containment. In buildings with high occupancy levels, gypsum plaster fire performance becomes a life-safety issue, not just a construction detail.

This is why hospitals, hotels, schools, and shopping centers almost always specify materials with a certified gypsum fire rating rather than standard plaster.

Fire Risk Level of the Space

One of the clearest indicators for when to use fire resistant gypsum is the fire load of the area.

Fire resistant gypsum plaster vs regular gypsum comparison shows that:

- Fire-rated gypsum maintains structural integrity longer

- Regular gypsum fails faster under sustained heat

Electrical rooms, generator areas, and storage zones should never rely on regular gypsum alone.

Insurance, Liability, and Risk Management

Insurance providers increasingly review fire resistant gypsum applications before approving coverage. Materials without documented fire resistance rating of gypsum systems may increase premiums or void policies altogether.

From a risk standpoint, the difference between fire resistant gypsum and regular gypsum directly affects legal responsibility in case of fire damage.

Cost vs Long-Term Safety Impact

Contractors often avoid fire-rated materials due to higher initial costs. This approach is short-sighted.

When comparing fire resistant gypsum plaster vs regular gypsum, it becomes clear that:

- Replacement and penalty costs exceed material savings

- Fire-rated systems reduce maintenance and retrofitting risks

In long-term planning, fire protection gypsum plaster is almost always the safer investment.

Cost Comparison and Long-Term Value Analysis

When evaluating gypsum materials, focusing solely on upfront price is a common mistake. A proper comparison must consider installation cost, lifecycle performance, regulatory compliance, and risk exposure, not just material price per ton.

Initial Material and Installation Costs

Standard gypsum products are generally more affordable and easier to install. Faster application and lower labor costs make them appealing for budget-conscious projects.

Fire-rated gypsum materials, on the other hand, typically involve:

- Higher material costs

- More controlled installation processes

- Strict compliance with tested system guidelines

At first glance, this creates a noticeable cost gap.

Maintenance and Retrofit Expenses

Cost differences become clearer over time. Materials used in fire-sensitive locations are often inspected during building audits or insurance reviews.

Non-rated gypsum systems may require:

- Partial replacement

- Additional cladding

- Structural modifications

These corrective actions often exceed the original savings achieved by using cheaper materials.

Regulatory and Approval Risks

Projects that fail to meet fire compliance standards may face:

- Construction delays

- Failed inspections

- Redesign costs

Materials with certified fire performance reduce uncertainty during approvals and handovers. This stability has measurable financial value, especially in commercial developments.

Insurance and Asset Protection

From an insurance perspective, buildings constructed with documented fire-performance materials are considered lower risk assets.

Benefits often include:

- Easier policy approval

- Potentially lower premiums

- Clear liability boundaries

In contrast, cost-cutting decisions involving non-rated materials may increase exposure in the event of damage claims.

Long-Term Return on Investment (ROI)

While fire-rated gypsum solutions increase initial expenditure, they often result in:

- Improved durability

- Reduced retrofit risk

- Better resale and leasing value

For long-term projects, especially in commercial and export-oriented developments, these factors significantly improve overall return on investment.

Common Mistakes When Choosing Gypsum Materials

Many problems related to fire safety and compliance are not caused by material quality—but by wrong material selection and poor decision-making. This section covers the most common mistakes contractors, developers, and buyers make when choosing gypsum products.

Treating All Gypsum Products as the Same

One of the biggest misconceptions in construction is assuming that all gypsum-based materials behave similarly under fire exposure.

In reality:

- Different formulations react very differently to heat

- Performance depends on internal composition, not just surface appearance

- Visual similarity does not equal functional equivalence

This mistake often leads to improper use in risk-sensitive zones.

Ignoring Tested System Requirements

Gypsum materials achieve fire performance only when installed as part of a tested system. Using the right material but applying it incorrectly can negate its fire-related benefits.

Common errors include:

- Incorrect thickness

- Missing layers or reinforcements

- Improper joint treatment

Even high-quality materials fail without system compliance.

Choosing Based Only on Initial Cost

Cost-driven decisions are a frequent cause of long-term problems. Selecting cheaper materials may reduce short-term expenses, but it often increases future risks.

Typical outcomes:

- Failed inspections

- Mandatory upgrades

- Unexpected replacement costs

This mistake is especially common in fast-track or budget-limited projects.

Overlooking Building Usage Changes

Many buildings change function over time. A residential space may later become a commercial or mixed-use environment.

If gypsum materials were selected without considering future use:

- Fire compliance may become insufficient

- Retrofitting becomes complex and expensive

Planning material selection with long-term adaptability in mind is often overlooked.

Lack of Documentation and Certification Review

Another critical mistake is failing to verify technical documentation.

Buyers often skip checking:

- Fire test reports

- Compliance certificates

- Applicable standards

Without verified documentation, material performance claims remain unproven and risky.

Poor Coordination Between Design and Execution

Designers may specify appropriate materials, but improper communication during execution leads to substitution on-site.

This disconnect can:

- Void compliance approvals

- Create legal exposure

- Transfer responsibility to contractors

Clear coordination across teams is essential for maintaining safety performance.

Final Comparison and Buyer Recommendation

At this stage, the differences are clear—but the final decision should be based on project risk level, regulations, and long-term expectations, not just price or availability.

Side-by-Side Summary (Practical Comparison)

Instead of technical overload, here is a simplified decision logic:

- Low-risk interior spaces with no fire compliance requirements → Standard gypsum materials are usually sufficient.

- Commercial, public, or multi-unit buildings → Enhanced fire-performance systems are strongly recommended.

- Projects requiring inspection, certification, or insurance approval → Documented and tested solutions reduce delays and liability risks.

- Export and international projects → Materials aligned with recognized fire standards offer smoother approvals.

How to Choose the Right Option for Your Project

Before purchasing gypsum products, decision-makers should ask four critical questions:

- Is fire resistance required by regulation or specification? If yes, non-rated materials immediately become a liability.

- What level of inspection or approval will the project face? The stricter the review process, the less tolerance there is for shortcuts.

- What is the expected lifecycle of the building? Short-term savings rarely justify long-term risks.

- Who carries responsibility after project delivery? Liability does not end at installation—it extends to performance.

These questions eliminate most wrong choices early.

Final Verdict for Buyers and Contractors

There is no universally “better” gypsum product—only context-appropriate choices.

- Budget-focused, low-risk environments benefit from simpler solutions.

- Safety-critical or regulation-driven projects demand materials with proven fire performance.

The real cost of a wrong decision is rarely visible at purchase time—but it surfaces during inspections, incidents, or ownership transfer.

Smart Purchasing Tip

For professional buyers:

- Always request technical datasheets

- Confirm fire test references

- Match materials to system-level approvals

Doing this upfront prevents expensive corrections later.

Get Certified Fire-Resistant Gypsum from Rezvan Mines

View technical specs, compliance documents, and product details.