The right gypsum product depends on several critical factors, including the application type, required surface quality, fire resistance, setting time, and long-term durability. To choose the right gypsum product, builders must evaluate whether the gypsum will be used for wall finishing, ceiling applications, decorative elements, or fire-resistant systems, while also considering compatibility with interior wall finishing materials and construction standards.

In modern construction projects, selecting the right gypsum product ensures smoother finishes, faster installation, reduced structural load, and improved safety performance. Understanding the different types of gypsum products, their technical properties, and their practical uses is the key to making an informed and cost-effective decision.

Introduction

Choosing suitable construction materials is one of the most critical decisions in any building project. The durability, safety, appearance, and long-term performance of walls and ceilings all depend on selecting materials that match the technical and environmental requirements of the space. Among interior finishing materials, gypsum-based products have become a preferred solution due to their versatility, speed of application, and consistent quality.

In today’s construction industry, understanding how to select the right gypsum product is no longer a choice but a necessity. With various types of gypsum products available—ranging from finishing gypsum plaster and putty powder to fire resistant gypsum plaster and micronized gypsum—making the wrong selection can lead to surface defects, increased maintenance costs, or performance failures over time.

This comprehensive guide is designed to help contractors, engineers, architects, and project managers make informed decisions when selecting gypsum materials. By exploring the different types of gypsum products, comparing gypsum plaster vs cement plaster, and analyzing key performance factors such as setting time, strength, and fire resistance, readers will gain a practical framework for identifying the right gypsum product for any interior or structural application.

Whether the goal is achieving a smooth decorative finish, reducing construction time, improving fire safety, or selecting construction grade gypsum that meets industry standards, this article provides expert insights that simplify gypsum product selection without compromising quality or performance.

What Are Gypsum Products?

Gypsum products are construction materials derived from natural gypsum rock, a mineral composed primarily of calcium sulfate dihydrate. After mining, gypsum is processed through controlled heating and grinding to produce different material grades suitable for various building applications. Today, gypsum products are widely used in interior construction due to their predictable performance, ease of application, and compatibility with modern building systems.

Understanding gypsum products at a technical level is essential before attempting to choose the right gypsum product for a specific project. Each gypsum-based material is manufactured with a particular purpose, setting time, particle size, and strength profile, making product selection a strategic decision rather than a generic choice.

How Gypsum Products Are Manufactured

The production process begins with raw gypsum stone extraction, followed by crushing and calcination. During calcination, gypsum is heated to remove part of the chemically combined water, converting it into calcium sulfate hemihydrate. This process determines whether the final product will be classified as construction grade gypsum, finishing gypsum plaster, or micronized gypsum used for high-precision applications.

The degree of grinding after calcination plays a critical role. Finely ground materials are typically used in putty powder for final coating and smooth decorative finishes, while coarser gypsum grades are applied in structural or base-layer plastering. This variation directly affects workability, bonding strength, and surface quality.

Why Gypsum Products Are Widely Used in Construction

Gypsum-based materials have become standard in interior wall finishing materials due to several performance advantages:

- Consistent setting time under controlled conditions

- Compatibility with different substrates such as concrete and brick

- Reduced need for water curing compared to traditional materials

- Lightweight structure that minimizes dead load on buildings

These characteristics make gypsum products particularly attractive for modern construction projects where speed, precision, and quality control are priorities.

The Importance of Selecting Correct Gypsum Materials

Not all gypsum materials perform the same way. Using an unsuitable product for a specific environment can result in cracking, poor adhesion, or reduced durability. For example, choosing decorative gypsum instead of fire resistant gypsum plaster in safety-critical areas can compromise building standards. Similarly, selecting low-quality gypsum materials may negatively affect long-term performance, even if the initial finish appears acceptable.

For this reason, builders and contractors must evaluate the intended application, environmental conditions, and performance requirements before deciding on the right gypsum product. A systematic selection approach helps ensure efficiency, compliance with standards, and optimal finishing results.

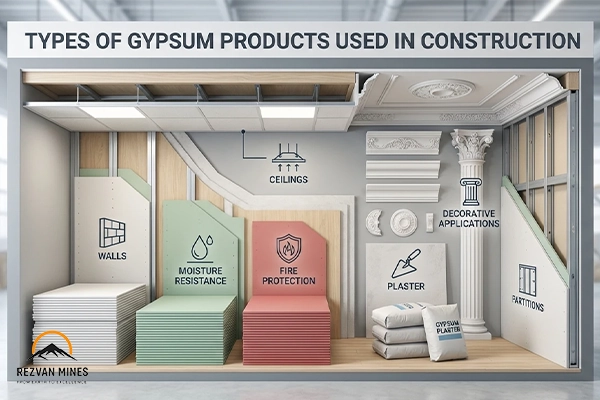

Types of Gypsum Products Used in Construction

Selecting the right gypsum product starts with a clear understanding of the different gypsum types available in the construction market. Each gypsum product is engineered for a specific purpose, application method, and performance requirement. Using the wrong type, even with high-quality raw material, can negatively impact surface finish, durability, or safety.

Below are the most common types of gypsum products used in modern construction projects.

Gypsum Plaster (Construction & Finishing Grade)

Gypsum plaster is the most widely used gypsum-based material for interior walls and ceilings. It is valued for its fast setting time, smooth surface finish, and excellent bonding properties. Depending on particle size and formulation, gypsum plaster can serve as a base coat or a finishing layer.

Builders often consider gypsum plaster when they need a clean, uniform surface with minimal curing time. Choosing this material carefully is essential when determining the right gypsum product for interior wall finishing applications.

Ready-Mix and Finishing Gypsum

Ready-mix and finishing gypsum products are factory-formulated materials designed for fine surface correction and decorative finishes. These products are commonly used after the main plastering stage to achieve a flawless appearance.

Because finishing gypsum has a smaller particle size, it delivers superior smoothness and is often paired with putty powder for final coating. This type is ideal for projects where aesthetic quality is a critical factor, such as residential interiors and commercial spaces.

Fire Resistant Gypsum Plaster

Fire resistant gypsum plaster is specifically designed to enhance fire safety in buildings. It performs by releasing chemically bound water when exposed to high temperatures, delaying heat transfer and structural failure.

Several studies have confirmed the effectiveness of gypsum-based materials in fire protection systems. For example, scientific research published on ScienceDirect highlights how gypsum significantly improves fire resistance performance in building assemblies:

scientific reference:

https://www.sciencedirect.com/science/article/pii/S095006181501299X

This makes fire resistant gypsum plaster a key component when safety regulations are a priority, especially in public buildings, corridors, and ceiling systems.

Micronized Gypsum

Micronized gypsum is a highly refined gypsum product with extremely fine particles. It is commonly used in specialized applications that require precise surface control, improved adhesion, and uniform texture.

Due to its enhanced reactivity and consistency, micronized gypsum is often selected for advanced finishing systems and high-end architectural details. In these cases, understanding material specifications is crucial to selecting the right gypsum product for performance-sensitive environments.

Putty Powder for Final Coating

Putty powder is a supplementary gypsum-based product used to eliminate minor surface imperfections before painting. Although it is not intended for structural leveling, it plays a key role in achieving visually perfect walls.

Using compatible putty powder alongside plaster systems improves the overall quality of interior wall finishing materials and ensures long-lasting paint performance.

Key Factors for Choosing the Right Gypsum Product

Choosing a suitable gypsum-based material is not just about brand or price. The performance of the final surface, project durability, and even long-term maintenance costs depend on how well the product matches the technical and environmental conditions of the project.

To make an informed decision, several key factors must be evaluated before selection.

Application Area and Surface Type

The first and most critical factor is the intended application area. Walls, ceilings, decorative elements, and repair sections each require different characteristics in terms of adhesion, smoothness, and flexibility.

For example, concrete substrates may demand stronger bonding performance, while brick or block walls benefit from materials with higher workability. Understanding the base surface helps prevent issues such as peeling, cracking, or uneven finishes later on.

Setting Time and Workability

Setting time directly affects application speed and labor efficiency. Fast-setting gypsum materials are ideal for high-speed construction projects, but they require skilled workmanship. Slower-setting products offer more working time and are better suited for detailed finishing or large surfaces.

Evaluating workability is essential when selecting the right gypsum product, especially in projects where application conditions are not perfectly controlled.

Surface Finish Quality

Different projects require different surface standards. Residential interiors often prioritize smooth, paint-ready surfaces, while utility or commercial spaces may only require functional finishing.

Finishing gypsum plaster and putty powder are typically chosen when high visual quality is required. Using inappropriate materials for final coating can increase sanding time and reduce paint durability.

Environmental and Safety Requirements

Environmental conditions play a major role in gypsum selection. Areas exposed to higher temperatures, increased fire risk, or specific building regulations require specialized materials.

Fire safety is one of the most important considerations. In regulated environments, the material must comply with fire resistance standards, making fire resistant gypsum plaster a mandatory option rather than a preference.

Compatibility with Other Materials

Gypsum products rarely operate alone. They are part of a system that includes primers, paints, and sometimes insulation layers. Incompatibility between materials can lead to delamination or reduced lifespan.

Choosing products designed to work together ensures consistent performance and reduces the risk of post-application failures. This systems-based mindset is crucial when determining the right gypsum product for professional construction projects.

Cost Efficiency vs. Long-Term Performance

Initial cost should never be the only decision factor. Lower-priced materials may increase labor costs, waste, or maintenance expenses over time.

A balanced approach considers material quality, application efficiency, and durability together. In most cases, a slightly higher-quality gypsum material delivers better overall value throughout the project lifecycle.

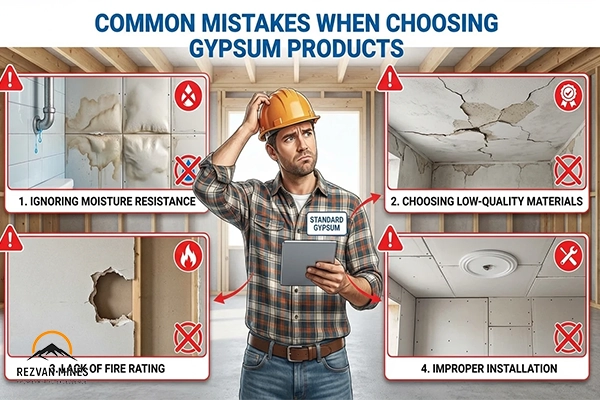

Common Mistakes When Choosing Gypsum Products

Even experienced builders and contractors sometimes make poor material decisions that lead to performance issues, surface defects, or additional costs down the line. Understanding these common mistakes helps professionals and homeowners avoid unnecessary complications when selecting the right gypsum product for their projects.

1. Ignoring Application Requirements

One of the most frequent mistakes is choosing a product without analyzing where and how it will be used. For example, applying standard gypsum plaster in high-moisture or high-temperature areas can severely reduce material durability.

Each environment demands different technical specifications—workability, water absorption, and reaction to heat. Reviewing these details with the manufacturer or supplier ensures your choice aligns with the project’s true conditions.

2. Overlooking Material Compatibility

Contractors sometimes mix different brands or types of gypsum in layered applications, assuming all products behave the same. In reality, mismatched formulations often cause uneven bonding, surface cracking, or inconsistent colors after painting.

Always confirm compatibility between gypsum layers, primers, and decorative coatings before starting work. A system-based approach ensures smoother application and long-term performance.

3. Choosing Low-Cost Products Over Long-Term Value

Many decision-makers still prioritize immediate savings rather than total project cost. A lower-priced material might save money upfront—but hidden expenses arise later through increased wastage, extra labor hours, and premature repairs.

The most efficient way is to balance cost efficiency with expected durability. High-quality gypsum materials typically lead to better finishing results and fewer callbacks, especially for large-scale or commercial projects.

4. Ignoring Surface Preparation

Even the best gypsum material cannot compensate for poor surface preparation. Dust, oil, or unprimed concrete reduce bonding strength and create visible surface flaws. Proper cleaning and priming are mandatory before plastering to ensure maximum adhesion and uniform appearance.

Neglecting this step is one of the top reasons behind deteriorated finishes and peeling problems seen months after project completion.

5. Neglecting Regulatory and Safety Standards

Fire safety regulations or environmental codes often define specific material categories for wall finishing. Using non-compliant products in regulated zones can result in rejected inspections or renovation costs later.

In such cases, selecting fire resistant gypsum plaster or certified finishing materials is not optional—it’s a regulatory necessity.

This topic is analyzed in detail in our previous in‑depth technical guide (https://rezvanmines.com/gypsum-plaster-benefits/).

6. Misjudging Setting Time During Application

Gypsum materials set at different speeds depending on humidity, temperature, and mixing ratio. Mismanaging this process can result in wasted material and uneven surface texture.

To minimize errors, always read manufacturer guidelines on mixing proportions and working time. Adjust your crew’s workflow accordingly instead of relying on assumptions or outdated habits.

7. Not Testing a Sample Before Full Application

Skipping small-scale testing can lead to large-scale regrets. Always apply a sample area to evaluate actual setting time, finish quality, and color match. This simple step helps ensure consistency before committing to larger surfaces.

Avoiding All These Mistakes

Learning from common errors streamlines project efficiency and saves both time and money. The key is adopting a data-driven, quality-focused approach to selecting and applying gypsum materials—ensuring that every decision contributes to a durable, compliant, and aesthetically perfect result.

Gypsum Product Selection for Different Applications

Different construction areas require different material characteristics. Understanding how gypsum products behave in specific applications allows professionals to achieve better performance, longer lifespan, and cleaner finishes—without unnecessary rework or material waste.

Instead of a one‑size‑fits‑all mindset, this section breaks down gypsum product selection by real-world usage scenarios.

Gypsum Products for Interior Walls

Interior walls represent the most common gypsum application. In these areas, bonding strength, workability, and surface smoothness are the primary concerns. Standard gypsum plaster is widely used due to its fast setting time and reliable adhesion to concrete and masonry surfaces.

For projects that demand higher visual quality, finishing gypsum plaster combined with putty powder ensures a uniform, paint‑ready surface. Selecting the right gypsum product here improves not only aesthetics but also paint longevity.

Gypsum Products for Ceilings

Ceiling applications place additional importance on weight, setting control, and crack resistance. Lightweight gypsum formulations are preferred to reduce stress on overhead surfaces.

In suspended or decorative ceiling systems, micronized gypsum is often chosen for its fine texture and controlled application behavior. Proper material choice minimizes sagging and surface irregularities over time.

Gypsum Products for High‑Traffic Commercial Spaces

Commercial environments such as offices, retail spaces, and public buildings require materials that can withstand wear and repeated maintenance cycles. Surface durability and compatibility with protective coatings become critical factors.

In these settings, gypsum materials with enhanced bonding characteristics and stable surface density deliver better long‑term performance. Selecting the right gypsum product for commercial use reduces repair frequency and operational downtime.

Gypsum Products for Fire‑Sensitive Areas

Certain zones—corridors, stairwells, and technical rooms—demand strict compliance with fire safety regulations. In these areas, fire resistant gypsum plaster plays a vital role in slowing heat transfer and improving structural safety during fire exposure.

Material selection in fire‑rated environments must be documentation‑driven and regulation‑compliant rather than experience‑based.

Gypsum Products for Decorative and Detail Work

Decorative elements such as wall moldings, niches, and architectural details require precision and surface refinement. Micronized and finishing-grade gypsum materials provide better control, sharper edges, and minimal post‑processing.

For these applications, material purity and particle consistency are more important than compressive strength alone.

Matching Application to Performance Expectations

Each construction zone has its own performance priorities—whether speed, appearance, safety, or durability. Matching these expectations with appropriate gypsum formulations is what separates average results from professional outcomes.

A context‑based selection approach drastically lowers material waste and ensures consistent results across different areas of the same project.

How to Identify High‑Quality Gypsum Products

As a project approaches execution, identifying product quality becomes more important than reviewing general specifications. Even within the same category, gypsum materials can vary significantly in performance, consistency, and finishing results.

This section outlines simple but effective indicators that help professionals distinguish reliable gypsum products from low-grade alternatives.

Consistency and Particle Uniformity

High-quality gypsum materials have uniform particle size and consistent texture. When mixed with water, they produce a smooth, lump-free paste that spreads evenly across the surface.

In contrast, inconsistent granulation often leads to uneven setting and visible surface defects after drying.

Controlled Setting Behavior

Reliable gypsum products set predictably under normal site conditions. Sudden or uneven setting is a common sign of poor formulation or improper processing.

Consistent setting provides better control during application and improves overall finish quality—especially for large wall or ceiling surfaces.

Adhesion Strength After Drying

Once cured, a quality product should form a strong bond with the substrate. Surface chalking, dusting, or flaking after drying is a clear indicator of inferior material quality.

Testing a small area before full application remains one of the simplest quality‑verification methods.

Manufacturer Transparency and Technical Data

Reputable manufacturers provide clear technical datasheets, including setting time, recommended layer thickness, and usage guidelines. The absence of documented specifications often correlates with unpredictable performance.

Professional projects should always rely on materials with traceable production standards.

Performance Over Appearance

A smooth finish at the time of application does not guarantee long-term durability. Quality evaluation must consider shrinkage, crack resistance, and surface stability over time—not appearance alone.

Prioritizing these performance indicators simplifies the process of selecting the right gypsum product without relying solely on price or brand popularity.

How to Choose the Right Gypsum Product with Confidence

Choosing the appropriate gypsum material is not a matter of preference, but a decision based on application, performance expectations, and long‑term reliability. Throughout this guide, we explored how different gypsum products behave under various conditions and why informed selection directly impacts surface quality, safety, and project efficiency.

To confidently select the right gypsum product, decision‑makers should focus on three core principles:

- Matching material type to the application area rather than using a universal solution

- Evaluating quality through consistency, setting behavior, and adhesion performance

- Prioritizing long‑term value, safety standards, and manufacturer transparency over short‑term cost savings

Whether the project involves interior walls, ceilings, commercial spaces, or fire‑sensitive zones, a structured evaluation process reduces errors and improves overall results. By treating gypsum selection as a technical decision rather than a routine purchase, builders and designers can ensure cleaner finishes, fewer repairs, and higher project reliability.

In modern construction, success lies not in using more material—but in choosing the right one.

If your project demands consistent performance, verified quality, and reliable technical support, Rezvan Mines offers gypsum products engineered to meet professional construction requirements.

Choose materials backed by expertise—and build with confidence from start to finish.